In the realm of speaker manufacturing, achieving precision and quality isn’t just a goal; it’s an art form. Public Addressing (PA) speakers and loudspeakers are pivotal in delivering clear, powerful sound across various environments, from auditoriums to concert halls, and even outdoor venues. Behind every exceptional speaker lies a meticulously crafted combination of components, each playing a crucial role in the overall performance and durability.

Let’s delve into the intricacies of these components, unraveling the secrets behind their contribution to precision and quality in speaker manufacturing.

1. Speaker Cone:

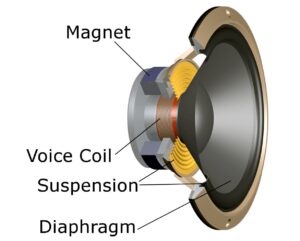

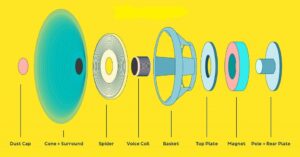

At the core of each and every speaker, the cone fills in as the essential transducer, changing over electrical signs into mechanical vibrations that produce sound waves. Accuracy in cone producing includes choosing materials known for their lightweight yet unbending properties, like polypropylene or aluminum. This guarantees ideal responsiveness and negligible bending, vital for exact sound generation.

2. Voice Coil:

Settled inside the speaker’s magnetic field, the voice loop goes about as the motor driving the cone’s development. Accuracy twisting of the voice loop utilizing great copper wire guarantees productive energy move and insignificant transmission misfortune. This outcomes in fresh, articulate sound conveyance across the recurrence range, from profound bass to taking off highs.

3. Magnet Assembly:

In the background, the magnet gathering gives the essential attractive transition to collaborate with the voice loop, prompting movement in the speaker cone. Neodymium magnets, known for their uncommon solidarity to-estimate proportion, are leaned toward in present day speaker plans for their minimization and strong attractive field, adding to upgraded effectiveness and devotion.

4. Surround Suspension:

Encompassing the external edge of the cone, the suspension framework assumes a critical part in keeping up with exact cone development while giving essential dependability. Top notch encompasses, frequently produced using elastic or froth, guarantee life span and flexibility against mileage, saving reliable execution over the long run.

5. Crossover Network:

In multi-driver speaker frameworks, the hybrid organization fills in as the director coordinating the circulation of frequencies to separate drivers, like woofers, tweeters, and mid-range drivers. Accuracy in hybrid plan is fundamental, guaranteeing consistent mix among drivers and reasonable sound result across the perceptible range.

Conclusion:

In the intricate tapestry of speaker manufacturing, precision is not merely a byproduct but the cornerstone of excellence. By understanding the crucial role each component plays in the grand symphony of sound reproduction, manufacturers can meticulously craft speakers that deliver unparalleled performance and durability. From the cone to the crossover, every element is a testament to the relentless pursuit of sonic perfection in Public Addressing and loudspeaker design.